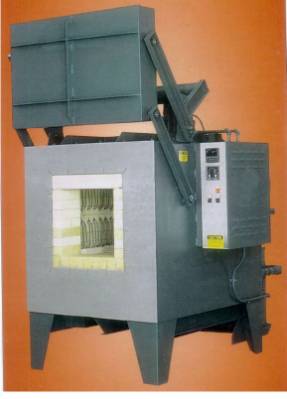

SAKAV standard 12000C heat treating furnaces are used for a variety of heat treating applications such as hardening, sintering or firing including those requiring inert atmospheres. Precision microprocessor based temperature controls and energy - saving insulation maximize the performance of these rugged units. Eleven standard models from 6.7 to 96 cubic feet, built for long, hard, continuous use.

- Digital microprocessor based, thermocouple actuated, indicating temperature controller.

- Modulating burner on gas furnaces

- Motor control push buttons and on-off heat switch.

- Easy-to-see pilot light.

Model |

Work Space Dimensions (W x D x H) |

Outside Dimensions |

Height W/Door Open |

Door Type |

Heat Input |

Operating Characteristics |

||||

KW |

BTU/HR |

Control Accuracy |

Furnace Uniformity |

Rise Time |

||||||

Electric |

Gas |

|||||||||

HD--183618-HT |

18" x 36" x 18" |

54" x 71" x 75" |

98" |

Electric |

34 |

425,000 |

+ 0.3% |

+ 60C |

180 min |

140 min |

HD-243618-HT |

24" x 36" x 18" |

60" x 71" x 75" |

98" |

Electric |

40 |

450,000 |

+ 0.3% |

+ 60C |

165 min |

145 min |

HD-244824-HT |

24" x 48" x 24" |

60" x 86" x 81" |

108" |

Electric |

53 |

600,000 |

+ 0.3% |

+ 60C |

150 min |

140 min |

HD-304830-HT |

30" x 48" x 30" |

66" x 86" x 87" |

116" |

Electric |

62 |

700,000 |

+ 0.3% |

+ 70C |

165 min |

140 min |

HD-306030-HT |

30" x 60" x 30" |

66" x 98" x 87" |

116" |

Electric |

66 |

725,000 |

+ 0.3% |

+ 70C |

180 min |

150 min |

HD-364836-HT |

36" x 48" x 36" |

78" x 86" x 126" |

126" |

Air |

72 |

800,000 |

+ 0.3% |

+ 100C |

180 min |

140 min |

HD-366036-HT |

36" x 60" x 36" |

78" x 98" x 126" |

126" |

Air |

80 |

850,000 |

+ 0.3% |

+ 100C |

180 min |

150 min |

HD-367236-HT |

36" x 72" x 36" |

78" x 110" x 126" |

126" |

Air |

92 |

1,000,000 |

+ 0.3% |

+ 100C |

180 min |

150 min |

HD-484836-HT |

48" x 48" x 36" |

90" x 86" x 126" |

126" |

Air |

84 |

915,000 |

+ 0.3% |

+ 100C |

180 min |

140 min |

HD-484848-HT |

48" x 48" x 48" |

90" x 86" x 150" |

150" |

Air |

100 |

1,100,000 |

+ 0.3% |

+ 100C |

165 min |

130 min |

HD-487248-HT |

48" x 72" x 48" |

90" x 110" x 150" |

150" |

Air |

145 |

1,500,000 |

+ 0.3% |

+ 100C |

140 min |

100 min |

Furnace shell is made of 3/16" thick steel plate reinforced with structural steel plate reinforced with structural steel. Powered door supported at rear by heavy-duty shaft and pillow block bearings. Open door exposes entire workspace for easy loading. Floating door construction provides excellent heat seal by pressing soft insulation against ½" thick steel top plate. Exterior painted with Trilite Green enamel. Each features completely wired, side access control panel assembled on the furnace enclosing terminals for incoming power, temperature controllers push buttons and pilot lights.

Safety devices as listed on the front of this bulletin. Heating element contractors electrically interlocked with door opens and restores power when closed. High temperature alloy wire heating elements supported in vacuum cast ceramic fiber. Heating elements located at four sidewalls.

- 1,000 BTU natural gas at 2 psig at 2 psig pressure; 1" NPT inlet up to 800,000 BTU/HR 1 ¼" NPT 850,000 to 1,000,000 BTU/HR

- Other gas characteristics available

Safety devices as listed on the front of this bulletin. Automatic preignition purge period and push button electric ignition contributes to ease of operation. Modulating gas burners fire from opposing sides to circulate heated air through the workspace. Gas burners protected with electronic flame safety relay. Door interlock switch drives main burners to low fire when door is opened and restores control when door is closed.

Door pivots upward above furnace, clearing top opening for easy loading. In the closed position, full door weight seats door firmly against furnace top plate. Structural steel pivot arms supported on furnace top plate by rugged pillow blocks are connected to a heavy-duty electromechanical actuator. A switch at the furnace control panel controls the door.

Door pivots upward above furnace, clearing top opening for easy loading. In the closed position, full door weight seats door firmly against furnace top plate. Structural steel pivot arms supported on furnace top plate by rugged pillow blocks are connected to a large diameter air cylinder. A manual air valve controls the door with supply filter, lubricator and regulator.