Bulletin WI-505

Low Cost Electric and Gas Ovens for

Convenient Truck Loading

Hardworking ovens designed for baking drying preheating or any other application where a dependable source of heated air to 2750C is required. Complete with temperature controllers that offer the latest in heat sensing technology and built-in floor level guide tracks that make truck loading easy.

Every oven fully assembled and individually factory tested.

| Model | Work Space Dimensions (WxDxH) |

Outside Dimensions (WxDxH) | Max Temp | Blower |

Insul- ation |

Doors | Heat Input | Operating Characteristics |

|||||

CFM |

HP |

KW |

BTU/ HR |

Control Accuracy |

Oven Uniformity |

Rise Time |

|||||||

Electric |

Gas |

||||||||||||

TA-275 |

36" x 36" x 60" |

52" x 63" x 70" |

2750C |

1000 |

¾ |

4" |

Double |

18 |

150,000 |

+ 0.3% |

+ 50C |

30 min |

15min |

TB-275 |

48" x 48" x 60" |

64" x 75" x 70" |

2750C |

1200 |

1 |

4" |

Double |

24 |

175.000 |

+ 0.3% |

+ 50C |

25 min |

15min |

TAH-275 |

36" x 36" x 60" |

52" x 63" x 70" |

2750C |

1600 |

1 ½ |

4" |

Double |

18 |

150,000 |

+ 0.3% |

+ 50C |

30 min |

15min |

TBH-275 |

48" x 48" x 60" |

64" x 75" x 70" |

2750C |

2000 |

2 |

4" |

Double |

24 |

175,000 |

+ 0.3% |

+ 50C |

25 min |

15min |

All Models 230 Volts, 3-Phase, 50 Hz.Other electrical characteristics available. Insulated floor with truck wheel guide tracks. Aluminized steel interior and Trilite Green enamel painted aluminized steel exterior.

Each features complete 230 Volts, 3-Phase, 50 Hz.ly wired, side access control panel enclosing terminals for incoming power, temperature controllers, push buttons and pilot lights. Motor starter and heating element contactors electrically interlocked to shut off heaters if power to blower without heat for cooling. Alloy wire-heating elements. Exhaust outlet 4" diameter Each features complete 230 Volts, 3-Phase, 50 Hz.ly wired, side access control panel enclosing terminals for incoming power, temperature controllers, push buttons and pilot lights. Motor starter and heating element contactors electrically interlocked to shut off heaters if power to blower without heat for cooling. Alloy wire-heating elements. Exhaust outlet 4" diameter.

- 1,000 BTU natural gas at 6" water column pressure, 1" NPT inlet. - Other gas characteristics available Control panel as detailed above and safety devices as listed on the front of this bulletin. Automatic preignition purge period and push button electric ignition contributes to ease of operation. Modulating gas burner is protected with electronic flame safety relay.

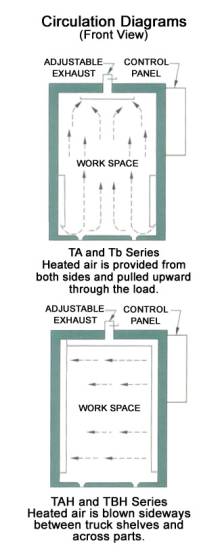

These electric or gas models come in two sizes. They feature combination vertical and horizontal airflow for truck processing of various size parts at temperatures to 2750C

Size 36" x 36" x 60" high provides 45 cubic feet of workspace. Truck tracks 2" wide, 24" center to center. Optional companion truck holds twelve 30" x 30" shelves on 4" centers.

Size 48" x 48" x 60” high provides 80 cubic feet of workspace. Truck tracks 2" wide, 36" center to center. Optional companion truck holds twelve 42" x 42" shelves on 4" centers.

Horizontal Air Flow Similar to TA and TB Series, these electric or gas models feature full horizontal air flow with adjustable patented opposed louvers on full coverage supply and return duct work. Used when vertical airflow through the load is restricted. Ideal for processing flat sheets, pans of parts or when shelves are densely packed Horizontal Air Flow Similar to TA and TB Series, these electric or gas models feature full horizontal air flow with adjustable patented opposed louvers on full coverage supply and return duct work. Used when vertical airflow through the load is restricted. Ideal for processing flat sheets, pans of parts or when shelves are densely packed

Companion Trucks and Shelves

Oven Model |

Truck Shelf Dimensions |

Maximum Shelves |

Truck |

TruckShelves |

|

700 lbs Capacity |

1200 lbs Capacity |

||||

| TA-500 TAH-500 |

30" x 30" | 12 | TRK700TA | TRK1200TA | SHLFTA |

| TB-500 TBH-500 | 42" x 42" | 12 | TRK700TB | TRK1200TB | SHLFTB |

Programmable Temperature Controller, microprocessor based, digital indicating, thermocouple actuated in lieu of standard controller................................................PTC3 · Recording Thermometer, thermocouple actuated, 24-hour, 10" diameter circular chart used in conjunction with standard controller.............RT · Programmable Recording Temperature Controller, microprocessor based, thermocouple actuated, digital display, 24-hour, 10 diameter circular chart, in lieu of standard controller........................................................................................................PRTC3 ·

Digital Timing System, incorporated into standard temperature controller, 99 hour 59 minute range, starts timing when temperature reaches set point and shuts down oven at end of set time............................................................................................................................DTS3 · Shut Down Timer, with continuous "hold" feature. 1,5,10 or 30 hour range........................................................................................SDT · Batch Timer, for uniformly timing batch operations. Continuous alarm with door interlock: alarms at end of preset time period until door is opened or timer reset. 1,5,10 or 30 hour range...............................................................................................................................BT · Automatic Door Switch turns off blower and heat when door is opened. Restores blower and heat on electric models, blower only on gas models, when door is closed..................................................................................................................... ADS

· Roof Mounted Powered Forced Exhausters Nickel plated wire shelves rated 100 lbs. uniformly distributed.